The Carmarthen Bay Wind Turbine Experiments

In the mid 20th century the UK Government, through its wind turbine test programme, encouraged commercial firms to develop and test horizontal axis wind turbines (HAWT) on various sites, e.g. Orkney. The ‘technological revolution’ espoused by PM Harold Wilson, the power of OPEC in the late 1960’s and early 1970’s, a recognition of the need for alternative sources of power, and initial environmental concerns were also important drivers in the research and development of wind power.

There are essentially two ways of seeking to harness the power of the wind. The oldest and most common type is the horizontal axis wind turbine (HAWT) in which the rotating axis of the turbine is horizontal, e.g. a windmill. The blades turn using the principle of aerodynamic lift but a rotational drive may also be required to adjust the blades to the wind direction. HAWT are resistant to ‘back tracking’ and are thus relatively efficient in that they produce more power from a given amount of wind but they need to be located in open areas. They are substantial physical structures with the gear box and control equipment at height. The blades are subject to alternating levels of stress due to inertial forces and gravity. This results in significant blade fatigue and the need for regular maintenance.

The alternative configuration is the vertical axis wind turbine (VAWT) in which the rotational axis is perpendicular to the ground. They have been used since the 7th.century. The basic design was modernised by a Finnish engineer in 1922 with a further enhancement by a French engineer in 1931. These enhancements involved aerofoil-shaped blades rather than cup-shaped blades thereby employing the more efficient aerodynamic lift forces to pull the blades rather than relying on the wind to push the rotor around. They operate in conditions where the wind conditions are not consistent in either strength or direction. However because not all of the blades produce torque at the same time, efficiency in the production of energy is limited. They have a low starting torque, are subject to “back-tracking” and dynamic stability and vibration problems that limit operational functionality. The blades are subject to much lower alternating loads and thus have greater longevity and lower maintenance costs. As structures they are usually less physically substantial than HAWT and the gear box and associated equipment is usually ground based.

One of the most significant developments in the 1970’s was the development of the Musgrove VAWT and its inclusion in the UK Governments wind turbine test programme as a competitor to the existing HAWT. Musgrove and research students at the University of Reading produced a prototype VAWT with a simplified and more efficient “H” configuration which was easier to manufacture. To limit excessive power production the turbine had an integrated reefing system which automatically feathered the blades – pointing them into the wind to reduce their surface area – in strong winds.

Given this background the Central Electricity Generating Board (CEGB), recognised the need to be involved in the evolving field of wind power generation. There was a need to assess the potential of and develop commercial-scale wind turbines for grid-electricity supply. As such, in 1978, it started its own wind power programme by undertaking meteorological assessments and reviews of the existing technologies before creating in the early 1980s an experimental wind farm on a coastal site near Burry Port. The site was adjacent to the out-of-service CEGB coalfired power station which was eventually decommissioned in 1984. The site, named “The Carmarthen Bay Wind Energy Demonstration Centre” had a visitor’s information centre which was visited by up to 16,000 people per year.

By hosting and testing wind turbines made by the three leading UK turbine manufacturers – James Howden, WEG and VAWT Ltd. – the CEGB wanted to act “as a shop window for UK designs” as well as offering the prospect of purchasing successful models once the testing had finished.

A number of wind turbines were installed and tested throughout the 1980s.

1982 – a 200 kW 3 blade HAWT with a blade diameter of 24.4 metres. (James Howden & Co.) This turbine – costing over £500,000 – was initially essentially a latticed pylon structure, some 80 feet tall. It could operate in an 8 mph breeze but reached maximum output at wind speeds of 30 mph producing enough power for 200 single bar electric fires. Wind speeds of 60 mph would trigger an automatic shut-down. Operational control was via an early computer from the USA. The turbine was switched-on on 16th November 1982 in the presence of the Chairman of the CEGB who stated that “the wind turbine was tangible evidence that the CEGB was interested in all forms of energy generation”.

In the first half of 1983 a routine overhaul and an urgent safety check on the blades following problems with a similar turbine in the USA had limited operational use to about 100 hours – enough to generate power for 12,000 single bar electric fires.

Subsequently this first foray into wind power was “disappointing due to a number of technical details, hydraulics, the blades and the data control system …… which severely limited its operation” Indeed it only operated for some 400 hours. However interest in the turbine was significant as both Thames TV and a delegation from Barbados visited the site.

1985 – a 28 kW 5 blade VAWT with a blade diameter of 6 metres. (Balfour Beatty Power Construction Ltd.) This was a shrouded vertical axis machine nicknamed the “Magic Mushroom” from its unusual appearance. This VAWT was 6 metres in diameter; the rotor comprised five vertical blades, spring-operated to avoid rotor over-speeding in high winds, and concentric with it a total eight ducts in a fixed dome-shaped shroud. This was designed to increase the amount of energy extracted from the wind. After 21 months of testing it was considered “non-cost effective”.

1986 – a 130 kW 2 blade VAWT with a blade diameter of 25 metres. (VAWT Ltd.) This, the first full-scale prototype Musgrove VAWT, was inaugurated on 28th.November 1986. The turbine consisted of a 25 metre diameter steel cross-arm of box construction with glass reinforced plastic fairings. It supported at each end 2 steel half-blades of elliptical section, 9 metres in length. The cross-arm was located at the top of a 25 metre high concrete tower of 2.8 metre diameter post-tensioned annular concrete ring construction. To allow for power control and safety shut-down, the pairs of half blades could be inclined through an angle of up to 70 degrees – “reefing” – by means of a hydraulically controlled actuating system located in the cross-arm. The tower housed a 2 stage transmission system with an upper low speed gear box and brake connected to a lower high speed gear-box and braking system. These in turn were connected to a 130kW rated generator system in a plant room at the base of the tower. A computer system protected the machine from spinning out of control and controlled the power output by ‘reefing’ the blades (essentially folding the “H” elements) to reduce the swept area. It also could brake and shut down the machine in high wind speeds.

1987 – a 300 kW 2 blade HAWT with a blade diameter of 30 metres. (WEG). This was a derivative machine to test the economical viability for commercial production and connection to the electricity grid. It used a steel rather than a concrete tower, light weight wood composite blades and a fully teetered hub. It generated power at two different rotor speeds: the standard speed of 48 rpm for maximum power (100 – 300 KW) and 32 rpm for power in light winds. The monthly availability of the turbine was around 50% and unattended operation was achieved with high reliability and low maintenance costs. The turbine was commissioned successfully and supplied power to the national grid for some two years. The environmental impact of this project was shown to be negligible with no objections being received by the local Authority responsible for the area.

Monitoring and testing was to last for at least 2 years along with studies for the design of a multi megawatt VAWT unit. The design was considered to be “a most promising renewable energy source” It was also “quite unique in the world as we believe it will have many advantages over other types currently in operation”.

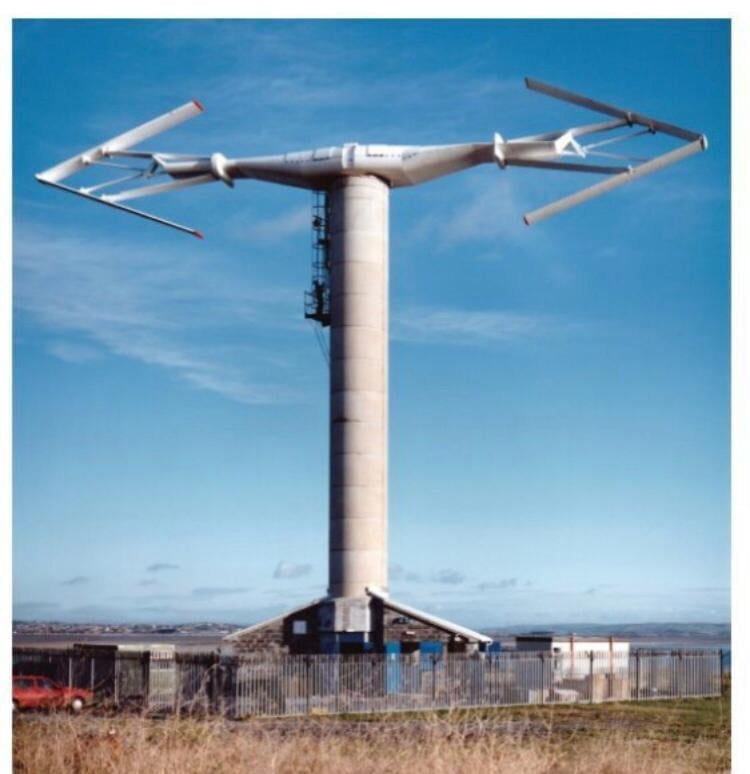

1990 – a 500 kW 2 blade VAWT with a blade diameter of 35 metres. (VAWT Ltd.) At the time this was Europe’s biggest VAWT standing 45 metres tall with a rotor diameter of 38 metres. It required a costly and substantial concrete tower structure with strength to withstand the alternating sideways forces produced by the rotating armature. The earlier tests with the 130kW VAWT had shown that the speed of rotation of the the wind turbine when generating was generally constant even as the wind speed varied as it was linked to grid frequency through the generators. Essentially the “H” design wind turbine naturally began to stall and selflimit power production in higher winds. Thus the complex, costly and practically unnecessary “reefing” system was not included in the design of the second prototype turbine. Testing started in August 1990 but one of the fibreglass blades failed due to manufacturing error on 26th.February 1991.

From all these developmental tests, operational data was collected and engineering lessons learned which were incorporated into subsequent wind power operations. Ultimately CEGB concluded that the best commercial prospects amongst the machines actually built and tested appeared to be with medium-sized machines with a capacity of 200 – 350 kW. Such machines were considered quieter, not too conspicuous and more easily assimilated into the landscape but there were concerns at the number required for the bulk generation of grid-electricity. However no UK manufacturer continued with a successful run of commercially marketed machines principally because of the lack of UK market support through ‘feed-in laws’, unlike the support given in Denmark, Germany and Spain for both manufacture and installation on their own networks.

Modern HAWT are increasingly cost-effective and more reliable, have scaled up in size to multi-megawatt power ratings and now dominate the grid-electricity scene worldwide. The Danish manufacturer Vestas is currently building and installing 15 mW wind turbines capable of powering over 13,000 homes each. Research has helped facilitate this transition, through the development of longer, lighter rotor blades – some turbines now have a rotor diameter of 236 metres (66% the height of The Shard in London), taller towers, more reliable drive-trains, and performance optimizing control systems. All this is being achieved through significant investment in technological innovation, enhancements in power generation and transmission, and engineering infrastructure to develop and service off-shore wind farms.

VAWT research is ongoing both for on-shore and off-shore locations. However the Musgrove ‘H’ type design has been superseded by alternative designs which are smaller in scale, of lower power output and more suitable to distributed power generation in urban areas.

Only one element of the Carmarthen Bay test site is now visible. Storms in the winter of 2018 eroded a section of the ash ponds related to the power station. Subsequently the entire octagonal base of the second Musgrove VAWT has been exposed a mile east of Burry Port harbour. The other bases, if they still exist as structures are covered by the vegetation of the Millennium Coastal Park. The base of the first Musgrove VAWT is under the curved landscape art, whilst the base of the 1982 3 blade HAWT is marked by the standing stone in a forest clearing at the end of a tarmac roadway. The precise location of the base of the 1987 2 blade HAWT is uncertain.

Burry Port thus had a role in the development of modern wind turbines, though one which has not been adequately exploited by the UK Government.

Sources

- Wind Engineering. Vol.30. 2006, Trevor J.Price.

- Wales Online. Llanelli Star – 17th.January 1981.

- Llanelli Star – 18th.September 1982; 20th.November 1982; 29th.January; 12th.March 1983; 12th.December 1986.

- Mr.Simon Powles

Paul Barrett. January 2022

The ‘Magic Mushroom’ is reproduce with permission from the the collections of the National Monuments Record of Wales: © Copyright: Central Office of Information Photographic Collection

The windmill ‘gif’ file is licensed under the Creative CommonsAttribution-Share Alike 3.0 Unported license.

If there are errors in copyright acknowledgement please inform us and we will rectify this or remove the image.