This is the abandoned site of the Copperworks and the other metal industries.

THE COPPER WORKS

1849 Copper works opens

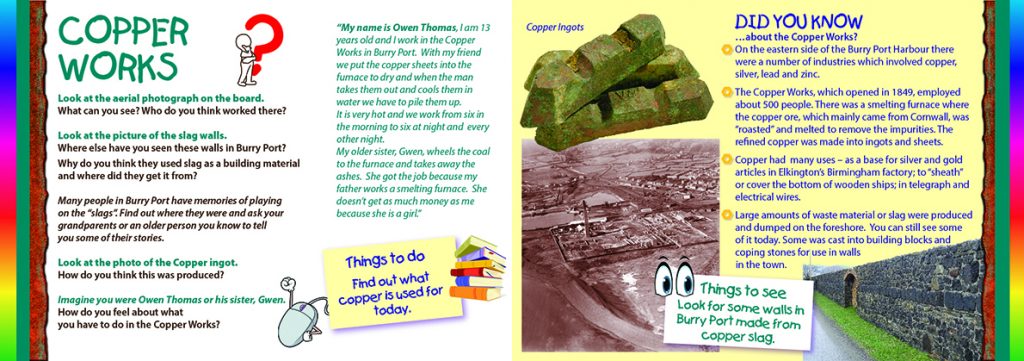

The Copper works became a major component in the development of Burry Port, employing large numbers in the works and even more in the company’s wider interests in the area. The wages varied within the works according to the job, your age and your experience also. The works comprised a smelting furnace where the copper ore was roasted and melted to remove the impurities. The refined copper was ladled into moulds to produce ingots and sheets. Depending on the origin of the copper ore, it could have a copper content of between 9-25% and so large amounts of waste material or slag were dumped on the foreshore where it made an ugly embankment. Although the metal content was low in these slags, as smelting became more efficient some of this slag was collected for smelting once again!

The Copper Works attracted other industries to the town, but it also benefitted from existing ones like coal mining, with the works management owning and running numerous mines in the vicinity. The works also established some new enterprises itself (see below) but finally closed as a copper smelting plant in 1912, primarily due to international competition based in or closer to copper ore producing countries, and increasing costs in manufacture and shipping of the finished product’

1853 Silver Works opens

A Silver Works was opened on the site to carry out Alexander Parkes’ patent process of smelting and refining silver. Some copper ores are rich in both silver and copper content, which the Pembrey Copper Works specialised in processing. Unfortunately the works closed down after only a year, presumably as it couldn’t be made profitable enough at the site alongside the copper smelting.

1865 Lead Works opens

Adjacent to the copper works the Burry Port Smelting Co Ltd established the Burry Port Lead Works. Many lead works at this time also smelted silver and the company may have helped build Silver Terrace in the Bacce to provide housing for the growing working population. The works were known as the “The Blue Lead Works” to differentiate it from the adjacent (and later) “Pembrey White Lead Works”.

The silver and lead ores were brought in by boat from overseas; in later years these came via Liverpool but could have originated from mines on the other side of the world. It is likely that the works used the patented Parkes process to refine the silver and lead as this method was growing in its efficiency at this time.

The lead and silver works closed in 1877 which coincided with a much wider economic slump that affected the whole country. The transport costs were blamed as they must have risen beyond what was considered profitable by the owners.

The lead the works produced was used in the numerous applications that can be found for lead, including being alloyed with other metals to produce a wide variety of compound materials with even more applications. To be clear, though, this works was concerned only with refining lead and silver.

1870 White Lead Works opens

In 1870 Risley and Burgmann built the Burry Port and Pembrey White Lead Works alongside the previously mentioned Lead Works. This was because all of the materials needed to produce white lead were available locally: lead, acetic acid, spent tanning bark (from the leather industry in Swansea and Llanelli), and horse dung! White lead was used at the time by potters to create a glaze on the pots they produced and was also a key ingredient in many paints of the time. The works also made its own paint and from 1902 also produced ink until 1905. From 1904 the works also smelted lead but this was closed down in 1910. At some point after the First World War the site was re-opened for refining copper, by the Cambrian Metal Co Ltd who were based there until the mid 1930’s although little is known of their success or failure in the attempt.

1918 Zinc Oxide works

This was developed on the old site of the Pembrey Copper Works and began the production of zinc oxide. Zinc oxide is an important industrial chemical pigment. At the time it was an ingredient in the manufacture of paint and rubber, but it was also used as a filler in plastic, in ceramics, textiles, matches, oil cloth, soap and more recently in the production of paper; in particular copier type paper.

During the First World War there was a shortage of zinc oxide and with governmental assistance numerous works were established to extract zinc oxide. In Burry Port, Metallic Chemicals Ltd was established by local colliery owner Evan Jones to manufacture several metal oxides, but primarily zinc. This was done by extracting the metal oxides from the flue-dust caked inside the old copper works! Once the war ended, the demand could once more be met by imported goods and the company closed.

The site was bought by Fricker’s Metal Co Ltd in 1922, also focussing on extracting zinc oxide and zinc dust. The company founder, Guy Carey Fricker, was a highly skilled electrical engineer who pioneered the zinc oxide industry in Britain. He established his first zinc oxide works in 1912 in Luton using his own patented processes.

During the 1920’s the works produced about 2,000 tons of zinc oxide a year which was half of what Frickers’ Luton works was producing. The company was sold to Imperial Smelting Corp Ltd in 1932, the largest zinc smelter operating in Britain at the time.

The Burry Port works, although smaller than the corporations other factories, was focussed on producing zinc oxides with the lowest lead content. Because of this focus on higher grades of zinc oxide, the works remained open through numerous company mergers and survived, while larger factories closed.

The list of owners is long and convoluted but the site’s final owner, Grillo Holding GmbH, acquired the site in 1991 and its name is synonymous with locals today with the old copper works site.

1947 Carmarthen Bay Power Station

Land to the east of the old copper works was cleared to build a new coal fired power station from 1947. Although the majority of the site occupied a previously undeveloped area, the copper works had used the area in the disposal of slag and waste, and so is worth mentioning along with the other industries that operated in the harbour area.

The architect was Sir Percy Thomas who designed many civic buildings such as the Swansea Guildhall.

The site was chosen as it offered easy access to sea-water for use as coolant, was easy to supply with coal by rail, and plenty of people were based close by to staff it.

The station was opened on 27th August 1954 and was operated by around 500 people who were mostly based in Burry Port. The station could produce 345-360MW using its six turbines to help meet the increase in demand of the mid 20th century.

The power station led an active role in the community supporting local institutions, events and charities. It stopped generating power in 1983 and demolition of the buildings began in 1991. Prior to the demolition the site was used briefly to test a number of wind turbine designs as part of a national programme.